Services of our team

We design

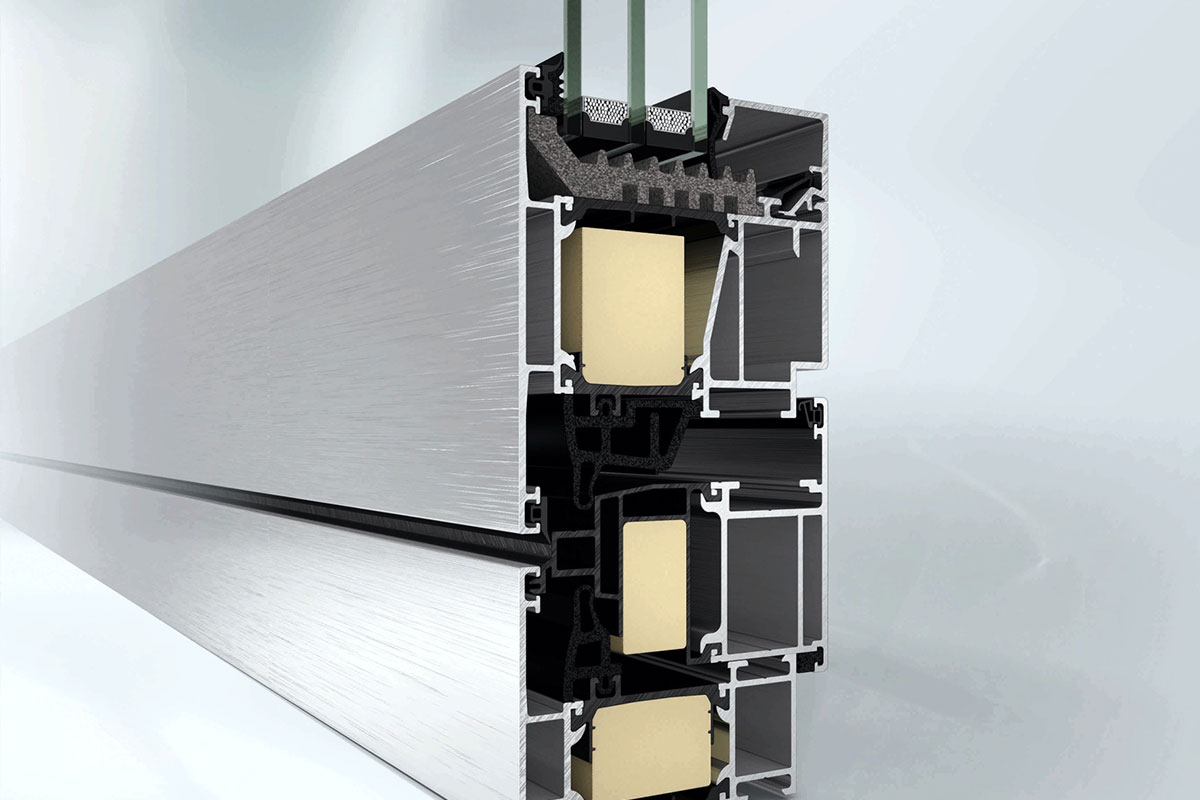

Units made with commercial or custom profiles. From the workshop drawing of each individual profile, to the final list complete with all the screws required for assembly, including the related fixing instructions. Possibility of supplying .stp files for insertion into the machine.

Mullions and transoms Facades of any commercial system, simple or reinforced, hanging or resting on carpentry. Committed materials. The counting of all the accessories supplied with the profiles both for the workshop and for installation on site.

From simple brackets to more complex carpentry.

Workshop details of each welded component and all the arrangements for anchoring the facade. Direct interface with engineers.

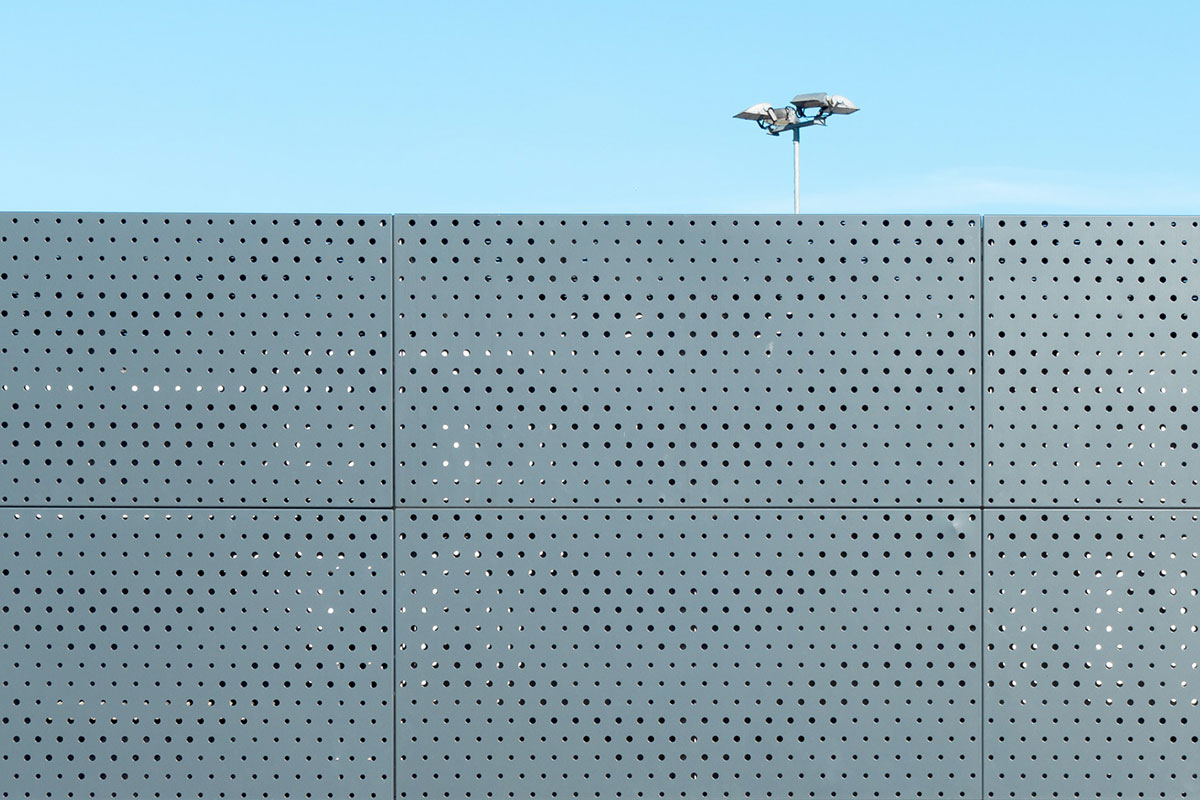

Rivestimenti in Alucobond, fibrocemento, e molte altre.

Studio della sottostruttra e di tutti i relativi agganci per il rivestimento.

Sheets inserted in Unit or in ventilated façade.

Construction for workshops with all cutting indications for any type and geometric shape of the slab.

Coperture vetrate in appoggio a strutture preesistenti, o strutture autoportanti realizzate su misura.

Ricostruzione e ottimizzazione dei passi modulari partendo dal wireframe architettonico.

Suspended ceilings in sheet metal or composite.

Study of all drainage, expansion and anchoring of the structure.

Internal and external balustrades, of any shape and material, designed to best connect with the existing facade.

Canopies of various types and materials, for commercial and residential buildings.

Abacus for doors and windows complete with accessories and codes for each individual profile. Machining and clamping for installation.

We provide

Bills for the order of all components and accessories for both the workshop and the construction site.

Search for the most functional but at the same time cheaper solutions for our customer.

Study of the movements and expansions of the various products based on the tolerances and project specifications.

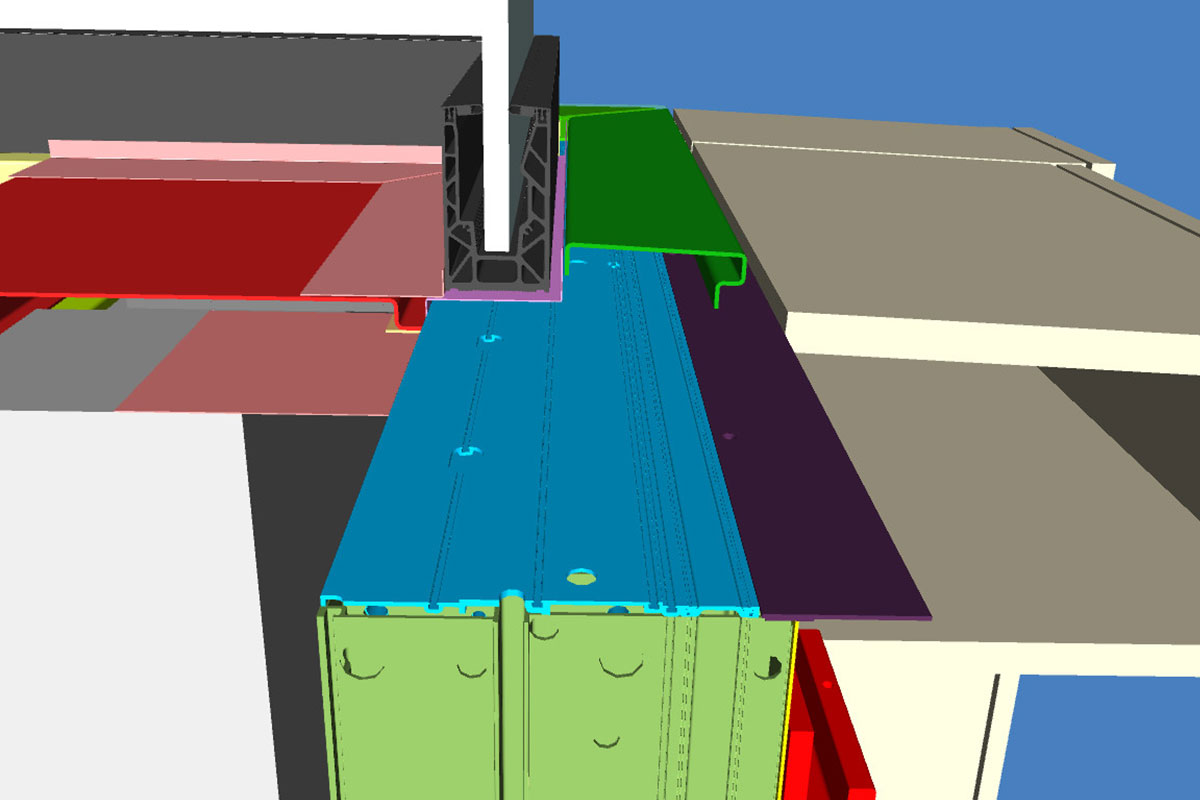

Dedicated studies through 3D modeling of the most complex areas of the building.

Execution of project tables (plans, elevations, details).

High detail level. Advanced use of drawing software.

Ability to adapt to the needs of the customer or the specific site.

Construction drawings in dwg, pdf or step format for direct insertion into the machining machine.

Execution of visual and performance mock-ups and any supporting carpentry.

Assistance with verification operations.

Detailed tables for the installation of all components.

Indication of screws and accessories to be used.

Operating instructions for the assembly of Cells.

All that is necessary to facilitate the installation.

Direct support to site personnel. Possibility of on-site assistance.

Highly specialized staff dedicated to the execution of BIM.

Possibility of BIM models up to LOD 500.

Constant updating during the design phase and the possibility of directly executing executive tables.

Use for direct extrapolation of the design tables of cements, steel structures, plants, etc.

Macro solutions for mass production thanks to the help of internal programmers.

Schedules aimed at managing each component of the construction site.

Dedicated programming, specific for automation.